Desert Sun and Seawater Farming

A surprising eco-logical form of farming turns cheap land, plentiful sun and nearby seawater into competitively-priced crops.

Farming in the desert, powered by the sun, using only seawater? Yielding large quantities of vegetables at competitive prices? This sounds to good to be true.

But true it is. In late 2016, Sundrop Farms began operating desert greenhouses in Australia that under normal conditions run entirely on solar energy and seawater. In them they hydroponically grow around 15% of the tomatoes purchased in Australia. They estimate their costs of production, including amortization of the up front capital expenditures, are 10% to 15% lower than competitors using traditional farming methods.

How did this come to be?

The story starts in London about thirty years ago. Lighting effects designer turned inventor Charlie Paton noticed something about photosynthesis relevant to greenhouse design.

Charlie Paton’s Pioneering Insights and Contributions

Founded in 1991, privately held

Designs and builds desert sun and seawater vegetable and fruit farming systems, tailored to climate and budget

Currently building a greenhouse-replacing, lighter weight shade netting desert sun and seawater farming system in Somaliland

Founder and Director: Charlie Paton

British, studied at Central School for Art and Design in London

Became a lighting and special effects designer

Invented several components of desert sun and seawater greenhouses

In the 1980’s Paton learned through his work in lighting design that photosynthesis is driven only by visible light waves. He realized that treated greenhouse glass could enable plants to grow and at the same time cut down on heat gain.

While vacationing in an arid location, he noticed condensation forming on a bus’s windows caused by humidity introduced after passengers with rain-soaked clothing boarded the bus and humidified the air inside. This got him thinking about pulling fresh water out of warm air by condensing it on surfaces cooled by seawater, just as water will condense on a bottle of cooled beer on a warm day.

As he was thinking about this, and about how to enable farming in arid climates, he realized there were two other key design challenges insufficiently addressed by greenhouses and thermal desalination: how to reduce the amount of water needed by plants, and how to keep plants cool enough.

Growing plants hydroponically addressed the need to reduce the amount of water needed.

Building on his insight about condensation, he realized he could use seawater in another way: to humidify and cool the air inside the greenhouse through evaporation. Ultimately he decided on directing air onto large hanging baffles of honeycombed cardboard soaked with seawater, either by orienting the greenhouse to take advantage of prevailing winds, or by using fans, powered by solar energy, to blow air on them.

Deserts aren’t only too warm for crops. In winter and at night they can also get too cool. To address this, sun-warmed seawater could be run through pipes inside the greenhouse to warm it up.

He also discovered that by letting humidity escape on the downwind side of the greenhouse (on the opposite side from the hanging seawater-soaked cardboard pads) an open area adjacent to a greenhouse could be sufficiently cooled and humidified to support arid-climate plants that otherwise would not be able to thrive, extending the area in which plant life could be supported.

Tinkering with and testing all the above variables using known technologies, Seawater demonstrated their aggregate efficacy in growing plants. The next steps were to build a pilot sun and seawater farm to learn how to maximize its efficiency and durability, and to develop a scalable business model attractive to investors.

This is where Philipp Saumweber and his company, Sundrop Farms, entered the picture.

Sundrop Farm’s Successful Operationalization of Desert Sun and Seawater Farming

Privately held, triple bottom line

Contracts with customers to deliver specified crops at specified prices on long term contracts, creating a farm to fulfill each contract

Has built two large sun and seawater farms, the first in the Australian desert and the second in Portugal

Founder and CEO: Philipp Saumweber

German, has MBA degree from Harvard

Former Goldman Sachs investment banker

Director in Saumweber Holdings, his family’s agricultural investment company

Saumweber, who had considerable experience in agricultural investment, saw the dominant farming model as “turning diesel into food and adding water,” an activity with many unattractive features to investors. Most importantly, farmers typically get stuck with all the risk inherent in both buying farming inputs (mainly fossil fuel derived electricity, gasoline, herbicides, pesticides, and fertilizer) and selling farm outputs, both at prices they can’t control. Making matters worse, both arable land and fresh water are becoming more scarce and therefore expensive, and fossil fuel pricing is becoming more volatile, and its use more clearly environmentally unsustainable.

He learned of Paton’s work, and saw it as a way to avoid many of these risks. Solar powered seawater-desalinating greenhouses could not only be environmentally sustainable, but also could make the cost of energy and water inputs predictable. They could allow a farmer to offer produce at predictable prices to food retailers throughout the year. Two key issues remained: Would it really work? Could it be done at a low enough cost?

In 2010 Sundrop Farms teamed up with Seawater Greenhouse to build a pilot sun-powered and seawater-converting 2,000 m2 greenhouse farm. It was located on dirt cheap land in a coastal desert area in Australia, a developed country, at Port Augusta: the second sunniest spot on earth (getting on average 320 days of sunshine a year), with unusually and usefully dry air for a location so close to the sea, and well-located to reach many of Australia’s population centers.

Sundrop Farms 2010 pilot greenhouse, done in partnership with Seawater Greenhouse

They began refining the pilot to increase efficiencies, upgrade component durability and performance, and grow a variety of crops. Part way through this initial proof-of-concept phase Sundrop and Seawater terminated their relationship. Saumweber had access to private capital, a team skilled in building robust, efficient, and therefore expensive industrial systems, and the goal of creating a profitable, scalable farming business growing produce for large scale grocers in developed countries. Paton was then and continues to be more oriented toward lower cost systems for developing countries to improve food security, as in his latest project in Somaliland. It was time for Sundrop to strike out on its own.

By 2014 Saumweber was confident that Sundrop’s operational model could deliver tasty high value vegetables, grown year-round with sustainable methods at predictably competitive prices. He also realized that by using sun and seawater as his primary inputs Sundrop would not be susceptible to production gaps due to Australia's frequent utility grid interruptions caused by increasingly frequent extreme weather events and grid operation related issues. With all these advantages, Saumweber landed a 10-year contract with Coles, a major Australian supermarket chain, to provide it a year-around supply of 17,000 tonnes of truss tomatoes a year at a fixed price.

Coles extremely long term contract reduced the risk for investment in a new method of farming with usually high upfront capital costs. It enabled Sundrop Farms to receive $100 million in financing from Kohlberg Kravis Robert (KKR) a global private equity firm. In addition, Australia’s Clean Energy Finance Corporation provided $40 million in debt financing, and they received a $6 million grant from the Australian Government to support their expansion plans.

This financing allowed them to build a facility 100 times as large as their pilot farm, as well as expand to other locations and countries. The expanded Port Augusta farm has 200,000 m2 (20 hectares) of greenhouse space and 23,712 mirrors to harvest sunlight and turn it into heat water and steam which can be used to generate electricity, desalinate water and heat greenhouses in cool weather.

Sundrop Farms Port Augusta four-greenhouse and solar farm facility completed in late 2016

Tomato plants are particularly well-suited for hydroponic production in greenhouses because tomatoes fetch a relatively high price, reach maturity much more quickly than field tomatoes, can be grown year around, and with supporting wires the plants can grow quite tall, maximizing the use of the cubic volume of the greenhouse and therefore the output per square meter of greenhouse floor space. Annually, they are able to raise 750 tonnes/hectare (334 US tons/acre) of tomatoes in their greenhouses.

In addition to being clean from an energy perspective, Sundrop’s methods are quite green from a farming perspective:

- Though the don’t grow their tomatoes in soil, they do use a proprietary plant nutrition formula that includes micronutrients to improve taste and nutrition.

- Bees are brought in on a monthly basis to pollinate the tomatoes.

- Coconut coir (husk), a repurposed waste from a renewable resource, is used as a nearly inert peat moss-like medium to support plant roots and maintain hydration between waterings.

- Their pest management system needs no herbicides, as there is no soil to attract weeds. To avoid the use of pesticides it depends on three lines of defense against ‘black hat’ insects: a surrounding desert climate inhospitable to them, salty humidity in greenhouse air they have found to be challenging, and white hat insects they introduce to attack the bad guys to reduce their populations.

Tomatoes in a 2016 Sundrop Farms Port Augusta greenhouse

Changes they have made to the initial pilot include include:

- Using maximally efficient systems and materials in the build out, with an estimated 25 year life span.

- Not harvesting salt and other minerals from waste brine, and instead returning it to the ocean, diluted and cooled to meet EPA requirements. Harvesting proved inefficient because of seasonal variations in seawater usage.

- Connecting to the utility grid to access water and power when they need it, either if there is a system failure, or on cold mornings when they’ve exhausted their 10-day supply of heated water or electricity. This compromise guarantees an uninterrupted supply of high quality tomatoes to their customers.

- Adding carbon dioxide to the greenhouse atmosphere to speed plant growth, a common tactic used in commercial greenhouses. To use an animal metaphor, plants ‘breath in’ carbon dioxide and ‘exhale’ oxygen. They source their CO2 from local energy producers who capture it instead of releasing it into the atmosphere. Note, however, it has recently come to light that growing crops in air with increased CO2 levels decreases nutrition levels in crops.

Sundrop Farms is to be commended for using desert sun and seawater farming to create a very environmentally sustainable and — in spite of practicing monoculture, growing only annuals, and replacing living soil with a chemical soup — a surprisingly eco-logical business that attracts private capital and is growing rapidly.

Desert Sun and Seawater Farming Used for Desert Reclamation

Privately held Norwegian company, triple bottom line

Mimics nature by integrating technologies that deliver value through creating complex biological systems with synergies that efficiently deliver many value streams and find uses for outputs that would be typically considered waste

Develops and promotes an environmental solution designed to utilize what we earthlings have enough of to produce what we need more of, using deserts, saltwater, sunlight and CO2 to produce food, water and clean energy

CEO: Joakim Hauge

Holds an MSc in biology from the Centre for Ecological and Evolutionary Synthesis at the University of Oslo

Green technology consultant

The oddly-named Sahara Forest Project (SFP) isn’t a project, but rather a company and foundation. From an eco-logical perspective, it’s goals are even more ambitious than Sundrop Farms. It seeks to:

- Turn desert back into arable land

- Get more value out of seawater through exploiting what it calls the saltwater value chain, in which a greenhouse is only one of four links in the chain.

- Mimic nature by adding more layers of complexity into a more closed-loop system, maximizing the use of local inputs and avoiding waste outputs.

SFP aims to simultaneously address five global challenges: food scarcity, energy consumption, climate change, water security, and desertification.

SFP’s Nature-Mimicking Biological Systems Approach

SFP is attempting to use triple bottomline criteria and a set of integrated technologies to mimic biological systems to maximize aggregate value delivered. They published the following chart comparing human-made to biological systems that parallels our six dimensions of farming eco-logic.

Human-made systems

Biological systems

Simple

Complex

Linear flows of resources

Closed loop flows of resources

Disconnected and mono-functional

Densely interconnected and symbiotic

Resistant to change

Adapted to constant change

Wasteful

Zero waste

Long-term toxins frequently used

No long-term toxins used

Often centralized and mono-cultural

Distributed and diverse

Fossil-fuel dependent

Run on current solar income

Engineered to maximize one goal

Optimized as a whole system

Extractive

Regenerative

Use global resources

Use local resources

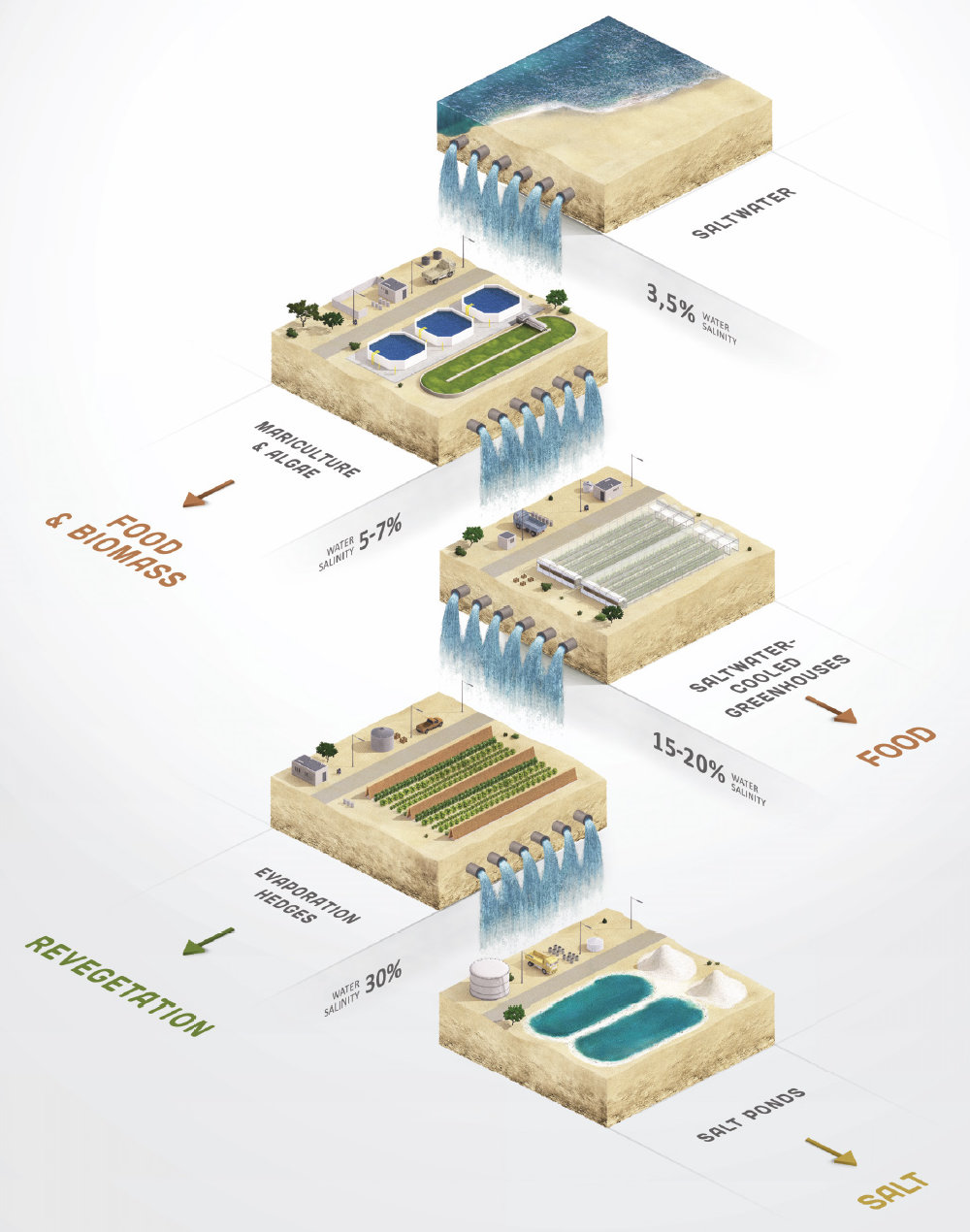

The Saltwater Value Chain

The SFP saltwater value chain is a four stage process that uses solar power combined with desalinated water and increasingly salinated water to create valuable outputs. The four core stages are shown below in this diagram from their website:

SFP also envisions adding not-yet-tested components to the value chain, especially in large scale applications, taking external and system generated inputs to generate useful outputs including:

- Bio-energy generators of biomass by either anaerobic digestion (where methane-producing bacteria digest biomass in an oxygen-poor environment) to generate biogas and nutrient rich digestive sludge or by pyrolysis (where decomposition is achieved through applying high temperatures) to generate bio-oil, syngas and carbon rich biochar.

- Livestock farming integrated with areas of the outdoor evaporation hedges. Livestock can add fertilization with their excretions, inexpensively harvest the fodder produced in these areas, provide revenue generating output like milk and eggs, self-replicate, and be harvested for meat.

- The use of waste CO2 from nearby industry to boost growth of algae and greenhouse crops.

SFP Progress to Date

Their first success was in Qatar, where they built a $5.3 million 1 hectare seawater value chain pilot facility they deemed a success that opened in December of 2012. It included:

- An area to grow halophytes (salt-tolerant plants)

- A pond to grow algae

- A greenhouse to grow vegetables

- An evaporative hedge area to grow arid-climate plants

- A facility to produce salt from highly concentrated brine

They reported publicly that they were able to quantify the scale of greenhouse operations that could replace Qatar imports of cucumbers, tomatoes, peppers and eggplants. The project was funded by two fertilizer companies. Funding for expanding the pilot to a larger scale production facility, however, did not materialize.

In October of 2016 they broke ground on a 3 hectare $3.7 million facility in Jordan, the first step towards realization of a 20 hectare facility. It includes the disassembled, shipped and reassembled Qatar pilot. Norway and the European Union are the two key funders of the project, along with Yara International (one of the fertilizer companies that funded the Qatar project), the Grieg Foundation, USAID and SFP itself.

Desert Sun and Seawater Farming’s Challenges and Potential

The three companies profiled above have all found ways to create valuable farming outputs from abundant, predictable, reliable, and inexpensive inputs: primarily sunlight, seawater, carbon dioxide and arid, degraded land. All therefore hold the promise to increase human food supply while at best also storing carbon in and adding fertility to depleted soil, and at worst causing remarkably few mild negative environmental consequences.

However, the approaches they took and the degree of success they have so far achieved differ. If they and emerging competitors continue in the directions each of these three have charted to date they will have different challenges and opportunities. To shift focus from these specific companies to the approaches they took, we refer here to the three directions as Approach 1 (taken by Seawater Greenhouse), 2 (taken by Sundrop Farms), and 3 (taken by Sahara Forest Project).

Approach 1

Challenges

This approach uses minimal means to achieve good enough results, targeting smallholder farmers, entrepreneurs and governments in arid, lower-income countries. Generating uptake for a very innovative approach to farming at or near the “bottom of the pyramid”, where consumers and business alike have little time and money to spend on methods new to them, and where efficiencies of scale are hard to achieve, looks to be the key challenge.

Potential

The approach has a large growth potential, measured by the number of farmers and food insecure areas it can serve. It could help small subsistence farmers take a leap forward in what they can produce. Given the focus, it is logical that Seawater Greenhouse is moving away from greenhouses toward nudging outdoor growing area air temperatures down and humidity up, using what they call a “shade net system” using “evaporative cooling elements” that enable farmers to grow native crops familiar to them while sequestering carbon and increasing the health of degraded soil.

Approach 2

Challenges

This approach appears to have the fewest challenges. It has been implemented at large scale in two locations (Port Augusta, Australia and Odemira, Portugal) and broken ground on a third farm in Tennessee. A formula has been developed that has attracted private equity, government funding and large corporate customers in high income economies.

Time will tell if their projections were accurate and they are able to profitably and reliably deliver produce to their customers over the years of their commitments.

Potential

This approach to desert sun and seawater farming has potential for continued speedy growth. It may be constrained, though, by the degree costs can be reduced to be able to grow lower and lower return crops. Currently Sundrop Farm’s high up-front build-out costs and high-income-economy labor costs limit it to growing what it calls “high value” crops: annual row crops sold as fresh produce to consumers through mass grocery channels. Crops in this category make up a tiny sliver of the cropland pie in high income economies. In the US, for example, only about 3% of cropland is used to grow fruits and vegetables.

Approach 3

Challenges

The most formidable challenge to this approach is the flip side of its most compelling feature: the mimicry of biological systems to take advantage of the synergies and complexities of abundant ecosystems. It requires finding markets for multiple outputs, recruiting or training farmers able to follow ecological principles and deploy appropriate technologies, and attracting investors and implementors comfortable with a system that is counterintuitive to most of what they have learned in business school and in their careers in big agriculture or in industry.

Potential

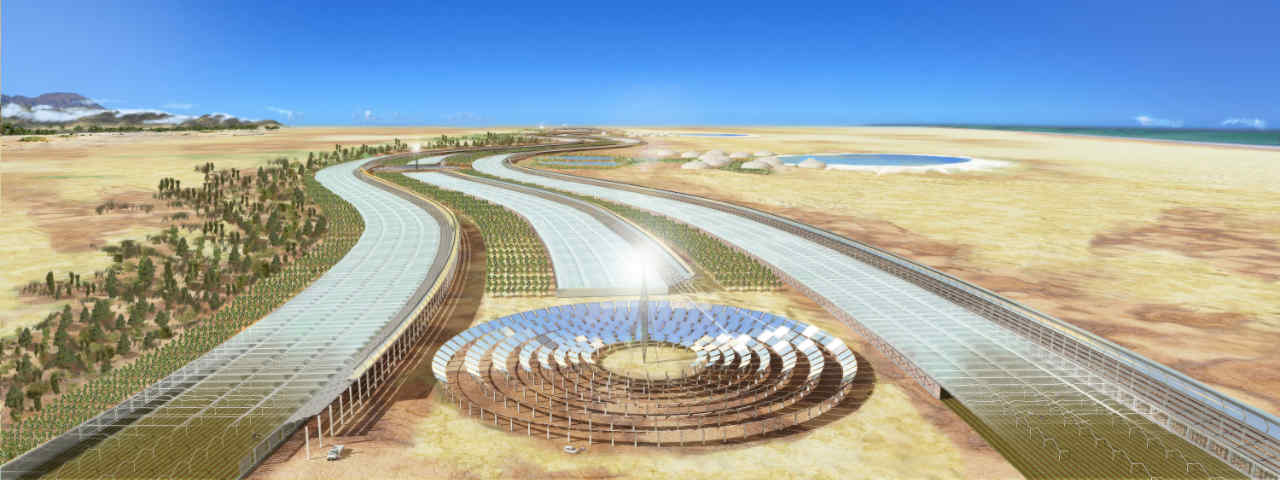

This approach is the most eco-logical of the three, making best use of inputs and of the synergies between plants and potentially between plants and animals, likely yielding the most impressive success in mitigating desertification. The emphasis on this goal, and the scale and complexity of the farms Sahara Forest Project proposes (shown below), suggests it needs considerable up front government or industry investment, perhaps integrated with rural economic development and town planning in middle income or above economies in deserts near the sea. It makes sense that Sahara Forest Project has had some success in finding support in relatively prosperous countries located in arid climes with limited farmland and hence little food security. But it is unclear why there is more uptake in countries with autocratic than with democratic governments.

Sahara Forest Project rendering envisioning a large scale implementation.